Dairy Heat Exchangers

Heat exchangers are essential in dairy processing, playing a key role in thermal treatments needed for pasteurization and cooling, ensuring food safety and maintaining product quality throughout various stages of production.

- Shell & Tube: Shell and tube heat exchangers offer robust performance and flexibility in dairy processing, ideal for handling large volumes of milk products.

- Plate & Frame: Essential for pasteurization and maintaining quality in milk processing, plate and frame dairy heat exchangers provide precise temperature control in a compact footprint.

- Clean-in-Place (CIP): Clean in lace (CIP) heat exchangers are vital for dairy applications, ensuring thorough, automated cleaning without disassembly.

- Materials: Various materials are available, including aluminum alloys, 304L stainless steel, and 316L stainless steel to name a few.

- Yogurt Production: Operators commonly select tube-in-tube, scrabped tube, or other specialty types of heat exchangers for viscous materials like yogurt.

- Liquid Egg: While not commonly thought of as "dairy," liquid egg products are another consumable that must go through pasteurization and processing.

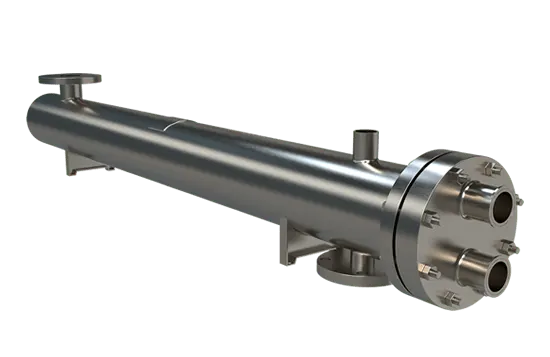

Shell & Tube:

Sanitary Models

- Evaporators & Condensors

- Clean-in-Place

- Stock and Custom Units Available

Plate & Frame:

Sanitary Applications

- Brewery & Distillery

- Food & Beverage

- Dairy Pasteurization

Heat Exchangers for Dairy Industry

Heat exchangers come in various forms, including plate and tubular designs, to accommodate different volumes and types of dairy products. They also contribute to energy conservation efforts by recovering waste heat from processed fluids and utilizing it to preheat incoming products. This not only reduces the thermal load on cooling systems but also decreases the overall energy consumption in dairy processing facilities.

Additionally, heat exchangers are crucial in the production of dairy products such as cheese and yogurt, where specific temperature profiles are necessary for fermentation and curd setting. The integration of these units within a dairy facility's process lines optimizes the plant's operational efficiency and achieves the requisite hygienic standards. Given their importance, these components are manufactured to comply with industry-specific sanitary regulations and designed for ease of cleaning and maintenance to prevent contamination and ensure consistent product quality.

Understanding the Need for Heat Treatment in Dairy Products

In the past, dairy goods were considered potential vectors for infections before heat treatment started to be used widely. This was because these products could serve as an excellent breeding ground for various disease-causing microorganisms like those leading to tuberculosis and typhus. Then extensive research bore fruit in the mid-19th century with the discovery of pasteurization, a concept conceived by Louis Pasteur, who researched the impacts of heat on dairy product microorganisms. His significant finding led to the adoption of heat as a tool for preservation and treatment. Through mild heat treatment, all harmful organisms likely found in milk are eliminated, making it aseptic and only slightly altering the product's physical and chemical makeup.

Of all probable organisms in dairy goods, the Tubercle bacillus (T.B.) is most resilient. This bacterium is eliminated when milk is heated for 10 minutes at 63°C. Safety can be assured when milk is heated for 30 minutes at the same temperature. T.B. is regarded as the index organism for pasteurization, meaning if a treatment can eradicate T.B., it can also wipe out other pathogens present in milk.

Effects of High-Temperature Exposure to Dairy Products

While microbiologically beneficial, the Ultra-high temperature (UHT) processing can compromise the appearance, taste, and nutritional integrity of milk products. High-temperature processing can denature proteins in milk and considerably alter its cheese-making property. Moreover, UHT can significantly influence the product's quality and flavor, emphasizing the importance of the right time/temperature combination, considering both microbiological and product quality implications.

Controlling Temperature in Dairy Products

Being able to manage the dairy product's temperature throughout the entire processing stages is crucial in ensuring quality. The most common heat mediums are hot water and low-pressure steam. Adequate heat is transmitted from the heat medium to the dairy product to increase the milk's temperature while decreasing the medium's temperature. Both substances need a substantial temperature disparity for effective heat transmission. The heat progresses from the warmer to the cooler substance, and a larger temperature difference leads to a speedier heat flow.

Regulative Heating and Cooling

Regulative heating and cooling process, utilized by most dairy producers, is instrumental in controlling temperature. This process is best exemplified in pasteurization, where chilled milk is warmed to 72°C, held at this temperature for 15 seconds, and then cooled to 4°C again. The heat from pasteurized milk is then repurposed for warming the incoming cold milk. This cycle is both energy and cost-efficient. To inhibit microbial growth, the milk must be chilled to below 5°C before and after pasteurization. Up to 94-95% of pasteurized milk's heat content can be recycled via this process known as regenerative heat exchange or heat recovery.

Types of Heat Exchangers in the Milk Industry

Milk heat exchangers are used in the milk industry to efficiently transfer heat during processes like pasteurization, cooling, and sterilization. The key types include:

Plate Heat Exchangers (PHE)

- The most commonly used heat exchanger in milk pasteurization.

- Consists of stacked metal plates with narrow channels for fluid flow, allowing for efficient heat transfer between hot and cold fluids.

- Suitable for rapid heating and cooling of large volumes of milk.

Tubular and Shell and Tube Heat Exchangers

- Tubular heat exchangers consist of tubes within a larger shell where one fluid flows inside the tube and another outside. They are designed to handle thicker fluids without clogging.

- A shell and tube heat exchanger works in a similar way to a tubular heat exchanger, facilitating heat exchange between fluids inside and outside the tubes.

- Ideal for viscous dairy products like cream, yogurt, or products containing particulates.

Scraped-Surface Heat Exchangers

- Used for products with high viscosity or those prone to sticking, like ice cream mix or concentrated milk.

- Has rotating blades to scrape the surface of the heat exchanger, ensuring consistent heat transfer and preventing buildup on the heat exchange surface.

Regenerative Heat Exchangers

- Often integrated into systems like plate heat exchangers, these exchangers capture heat from pasteurized milk to pre-warm the incoming raw milk, improving energy efficiency.

Clean-in-Place Heat Exchangers (CIP)

- CIP heat exchangers enable automatic and thorough cleaning without requiring disassembly.

- By circulating cleaning solutions through the system, CIP ensures effective sanitation and hygiene, removing residues and preventing contamination in dairy processing.

These heat exchangers are vital in ensuring the safe and efficient processing of milk and dairy products, maintaining product quality, and reducing energy consumption.