Demineralized Water Heat Exchangers

The design of these heat exchangers varies widely, adapted to meet specific thermal loads, flow rates, and temperature ranges characteristic of the diverse processes they support. With focuses on efficiency, durability, and ease of maintenance, demineralized water heat exchangers are tailored to meet the demanding environments in which they operate.

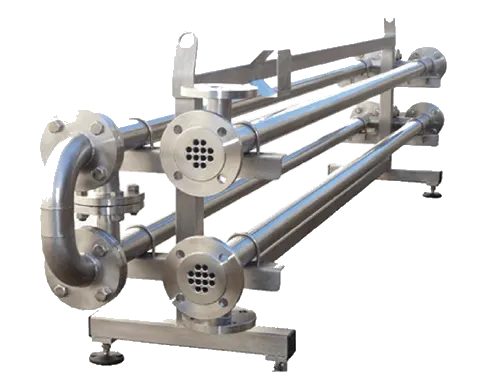

Tube-in-Tube RO Water Exchangers

Likewise, tube-in-tube heat exchangers present a solution when dealing with more viscous fluids, like those laden with fibers, particles, or with a thicker constitution. The use of concentric tubes- sometimes with corrugated surfaces- amplifies the rate of heat transfer while optimizing space. In scenarios where aggressive fluids are involved, more robust materials such as duplex stainless steel are used to help extend longevity.

Brazed Plate

Brazed plate heat exchangers, recognized for their compactness and maintenance-free performance, also achieve highly efficient temperature modulation for RO water. They stand as cost-effective options for RO water applications, facilitating tight approach temperatures between the utility and process fluids.

Gasketed Plate & Frame

Lastly, plate and frame exchangers represent a popular choice in this arena, bringing robust construction suited for the high purity requirements of RO water heat transfer. Such exchangers utilize gaskets that vary in composition to suit the unique demands of different industrial processes. Gasketed plate exchangers offer easy servicing and gasket or plate replacement, unlike other types of units.

Heat exchangers specifically designed for RO water are instrumental in various processes across industries involving pharmaceuticals, biotechnology, and more. Their critical role in heating, cooling, steam generation, and other temperature-sensitive procedures underlines their significance to sanitary and industrial operators in maintaining process efficiency and operational longevity.

Common FAQs

Demineralized water, also called deionized water, is water that has had the majority of its mineral ions removed through processes like ion exchange. This leaves the water free of dissolved salts and other charged particles, making it pure. Unlike distilled water, which is purified through boiling and condensation, the demineralized water process removes dissolved charged particles without the use of heat.

Demineralized water is used in industrial processes where the absence of minerals is essential to avoid scaling, corrosion, or contamination. It is also used in laboratories and electronics manufacturing because of its high purity.

The type of water used in heat exchangers depends on the application and the specific system requirements. Common types of water include:

- Deionized Water (DI Water): This highly purified water is used in sensitive applications, like pharmaceuticals and electronics manufacturing, to prevent contamination and scaling due to the absence of minerals and ions.

- Demineralized Water: Similar to deionized water, demineralized water has had most of its mineral ions removed, which prevents scaling and corrosion in demineralized water heat exchangers. This water is used in industrial cooling systems, power plants, and boilers. Demineralized water can achieve near-total removal of dissolved ions, making it suitable for industries like pharmaceuticals and electronics manufacturing. Even trace amounts of ions can cause issues in heat exchangers in these industries.

- Tap Water: In less critical applications, regular tap water may be used. However, it can cause scaling and corrosion over time due to its mineral content, so it is less ideal for long-term use in heat exchangers.

- Distilled Water: Distilled water is another option that is free of minerals, making it a good choice to avoid buildup in heat exchangers. It is used in smaller, more controlled systems.

In systems where scaling and corrosion are concerns, itís common to use treated or purified water, like deionized or demineralized water, to maintain the effectiveness and longevity of the heat exchanger.

The most common method used to produce demineralized water is ion exchange. This process removes mineral ions, like calcium, magnesium, sodium, chloride, and sulfate, which are responsible for scaling and corrosion in systems like boilers and cooling towers. Ion exchange passes water through resins that replace unwanted mineral ions with hydrogen and hydroxide ions, resulting in pure water. There are two primary resins used in this process:

- Cation exchange resins remove positively charged ions (like calcium and magnesium).

- Anion exchange resins remove negatively charged ions (like chloride and sulfate).

Other methods for demineralizing water include:

- Reverse Osmosis:Water is forced through a semi-permeable membrane that blocks dissolved salts and impurities.RO water, while effective at removing a large portion of impurities, might still contain small quantities of dissolved salts and minerals, making it slightly less pure than demineralized water for applications that require ultra-pure water.

- Distillation:Water is boiled and then condensed, leaving behind minerals and impurities.

When comparing demineralized water vs. RO water, demineralized water offers higher purity since ion exchange removes nearly all ionized minerals, making it ideal for applications like pharmaceuticals and electronics. A demineralized water system doesnít require the high-pressure pumps used in RO systems. Demineralized systems tend to need less maintenance, whereas RO systems require frequent cleaning to prevent membrane fouling. This makes demineralized water preferable for ultra-pure needs.

The most efficient demineralized heat exchanger depends on the specific application and system requirements, but plate heat exchangers are considered the most efficient for handling demineralized water. Their compact design provides a large surface area for heat transfer, resulting in high thermal performance. Plate heat exchangers allow easy cleaning and maintenance, reducing the risk of fouling, which is essential when using demineralized water, as it can be aggressive toward certain materials.

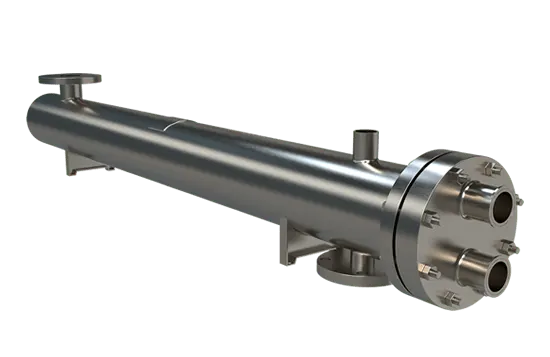

Shell and tube heat exchangers are also effective in high-pressure applications, but plate heat exchangers offer better energy performance and heat transfer in systems where demineralized water is used.

Choosing the right material, like stainless steel or titanium, is important to ensure compatibility with demineralized water and prevent corrosion.